Share

Pin

Tweet

Send

Share

Send

Currently, many voltage regulators are produced and most of them are made on thyristors and triacs, which create a significant level of radio interference. The proposed interference regulator does not give at all and can be used to power various AC devices, without any restrictions, unlike triac and thyristor regulators.

In the Soviet Union, a lot of autotransformers were produced, which were mainly used to increase the voltage in the home electrical network, when the voltage dropped very much in the evenings, and the LATR (laboratory autotransformer) was the only salvation for people who wanted to watch TV. But the main thing in them is that at the output of this autotransformer, the same regular sine wave is obtained as at the input, regardless of voltage. This property was actively used by amateur radio enthusiasts.

LATR looks like this:

The voltage in this device is regulated by rolling a graphite roller along the bare turns of the winding:

The interference in such a LATR, nevertheless, was due to arcing, at the moment of rolling the roller along the windings.

In the journal "RADIO", No. 11, 1999, page 40 published the article "No-noise voltage regulator".

Scheme of this regulator from the journal:

In the regulator proposed by the magazine, the shape of the output signal is not distorted, but the low efficiency and the inability to obtain increased voltage (above the mains voltage), as well as outdated components that are problematic to find today, negate all the advantages of this device.

Scheme of electronic LATR

I decided, if possible, to get rid of some of the shortcomings of the regulators listed above and preserve their main advantages.

From LATR we take the principle of autotransformation and apply it on a conventional transformer, thereby increasing the voltage above the mains voltage. I liked the transformer from the uninterruptible power supply unit. Mostly because it does not need to be rewound. Everything you need is in it. Transformer brand: RT-625BN.

Here is his diagram:

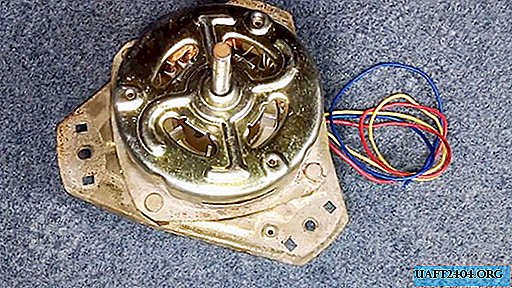

As can be seen from the diagram, in addition to the main winding of 220 volts, there are two more, made by a winding wire of the same diameter, and two secondary powerful ones. Secondary windings are great for powering the control circuit and the operation of the power transistor cooling cooler. Two additional windings are connected in series with the primary winding. The photographs show how this is done by color.

We supply power to the red and black wires.

The voltage from the first winding is added.

Plus two windings. Total turns 280 volts.

If you need more voltage, you can still wind the wires until the transformer window is full, having previously removed the secondary windings. Only you need to wind it in the same direction as the previous winding, and connect the end of the previous winding to the beginning of the next. The turns of the winding should, as it were, continue the previous winding. If you wind towards, then when you turn on the load will be a big nuisance!

You can increase the voltage, if only the regulating transistor can withstand this voltage. Transistors from imported TVs are found up to 1500 volts, so there is scope.

The transformer can be taken any other that suits you in terms of power, remove the secondary windings and wind the wire to the voltage you need. In this case, the control voltage can be obtained from an additional auxiliary low-power transformer for 8 - 12 volts.

If someone wants to increase the efficiency of the regulator, then here you can find a way out. A transistor uses power unnecessarily to heat up when it has to greatly reduce voltage. The stronger you need to reduce the voltage, the stronger the heating. In the open state, the heating is negligible.

If you change the circuit of the autotransformer and draw on it many conclusions of the voltage levels you need, then you can use the switching of the windings to apply a voltage close to the current one that you need at the transistor. There are no restrictions on the number of transformer leads; only a switch corresponding to the number of leads is needed.

In this case, the transistor will be needed only for insignificant accurate adjustment of the voltage and the efficiency of the controller will increase, and the heating of the transistor will decrease.

LATR fabrication

You can start assembling the regulator.

I modified the diagram from the magazine a bit, and this is what happened:

With such a circuit, the upper voltage threshold can be significantly increased. With the addition of an automatic cooler, the risk of overheating of the regulating transistor is reduced.

The case can be taken from an old computer power supply.

Immediately you need to figure out the order of placement of the device blocks inside the case and provide for the possibility of their reliable fastening.

If there is no fuse, then it is necessary to provide another protection against short circuit.

The high voltage terminal block is securely attached to the transformer.

On the output, I put a socket for connecting the load and voltage control. A voltmeter can be put any other, at the appropriate voltage, but not less than 300 volts.

Will need

We will need the details:

- Cooling radiator with cooler (any).

- Bread board.

- Contact pads.

- Details can be selected based on the availability and compliance with the nominal parameters, I put what first came to hand, but chose a more or less suitable one.

- Diode bridges VD1 - at 4 - 6A - 600 V. From the TV, it seems. Or assemble from four separate diodes.

- VD2 - at 2 - 3 A - 700 V.

- T1 - C4460. I put the transistor from an imported TV at 500V and a dissipation power of 55W. You can try any other similar high-voltage, powerful.

- VD3 - diode 1N4007 to 1A 1000 V.

- C1 - 470mf x 25 V, it is better to increase the capacity even more.

- C2 - 100n.

- R1 - 1 kOhm any wirewound potentiometer, from 500 Ohm and above.

- R2 - 910 - 2 watts. Selection of the current base of the transistor.

- R3 and R4 - 1 kΩ each.

- R5 is a 5 kΩ subscript resistor.

- NTC1 - 10 kOhm thermistor.

- VT1 - any field effect transistor. I put RFP50N06.

- M - cooler 12 V.

- HL1 and HL2 - any signal LEDs, they can not be installed at all together with quenching resistors.

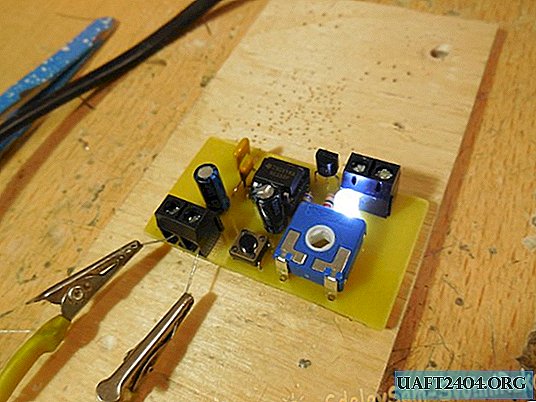

First of all, you need to prepare a board to place the parts of the circuit and fix it in place in the case.

We place the details on the board and solder them.

When the circuit is assembled, it is time for its preliminary testing. But you need to do this very carefully. All parts are live.

To test the device, I soldered two 220 volt bulbs in series so that they would not burn out when 280 volts went to them. The same power of the bulbs was not found and therefore the glow of the spirals varies greatly. It must be borne in mind that without a load the regulator works very incorrectly. The load in this device is part of the circuit. The first time you turn it on, it’s better to take care of your eyes (all of a sudden they messed up something).

Turn on the voltage and use a potentiometer to check the smoothness of voltage regulation, but not for long, in order to avoid overheating of the transistor.

After the tests, we begin to collect the automatic cooler operation scheme, depending on the temperature.

I did not find a 10 kΩ thermistor, I had to take two of 22 kOhm and connect them in parallel. It turned out about ten ohms.

We fix the thermistor next to the transistor using a heat-conducting paste, as for a transistor.

We install the remaining parts and solder. Do not forget to remove the copper pads of the breadboard between the conductors, as in the photo, otherwise, when you turn on the high voltage, a short circuit may occur in these places.

It remains to adjust the start-up of the cooler with a trimmer resistor when the radiator temperature rises.

We put everything in the case in regular places and fix it. We finally check and close the lid.

Please see the video of the noiseless voltage regulator.

Good luck to you.

Share

Pin

Tweet

Send

Share

Send