Share

Pin

Tweet

Send

Share

Send

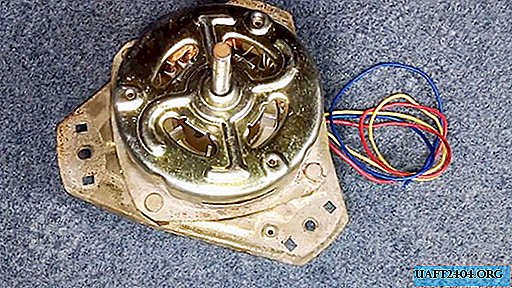

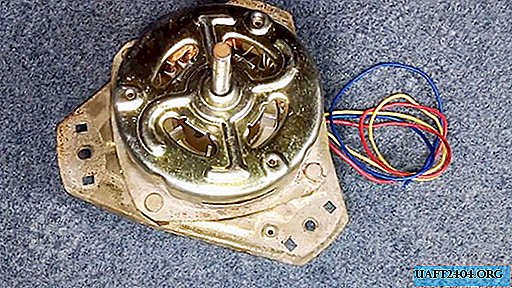

Anyone familiar with the design of an induction motor knows very well that he will not work just like that in generator mode. The thing is the lack of a magnetic field capable of creating an electromotive force in the windings of its stator. But what happens if you modify the rotor of the motor with permanent magnets? In essence, a generator should be able to convert mechanical energy into electric current. Let's check.

Will need

- Neodymium magnets, in a large number and of various shapes, can be purchased on AliExpress.

- Two-component adhesive - epoxy.

- Masking tape.

Converting an induction motor into an alternator

We open the engine housing by unscrewing the fixing screws. Remove the cover of one of the sides.

We pull out the anchor, it is a squirrel-cage rotor.

Inspect the stator for damage, just in case for damage. And determined by the alternation of permanent magnets.

Neodymium magnets are flat and round because they will be easier to install.

We occupy an approximate arrangement of magnets on the rotor.

We glue the anchor with masking tape, repeat the arrangement.

For clarity, draw the poles of magnets.

We drill blind holes in diameter and thickness of the magnets. We dilute the epoxy resin and glue the magnets into the recesses flush.

We paint all parts of the electric motor for aesthetic appearance and protection against corrosion.

Install the rotor back. We assemble in the reverse order.

We fix the engine cover bolts.

Generator check

We connect a drill or screwdriver to the motor shaft.

We provide rotation. As you can see, the output voltage is present.

Now connect the load. This is a 220V and 5W fluorescent lamp. Since the motor is three-phase, to concentrate energy at one point, we shunt the free winding with a capacitor.

The lamp shines brightly, almost like from a network.

Power, voltage, required torque - all this will depend on the model of a particular electric motor.

Conclusion

In this example, a generator was created that required high revs. Theoretically, of course, it can be used, say, in a windmill and relieve a small voltage of about 20-30 V. It will work quite well, since there is practically no magnetic sticking in it and the wind will rotate the blades without extra effort.

Share

Pin

Tweet

Send

Share

Send