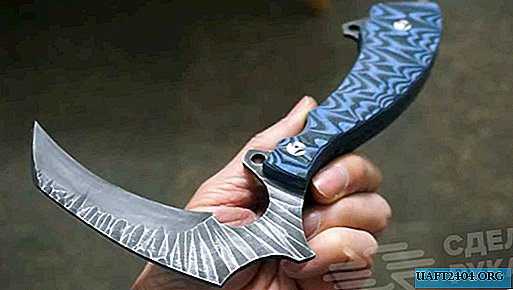

For the manufacture of the original sickle-shaped knife, the master uses an old saw blade on wood for a circular saw. First of all, you need to cut a knife blank using a paper template.

After that, the master processes the L-shaped workpiece cut from the saw blade on a belt grinder, aligning the edges and removing burrs after cutting with a grinder. Further, a manual file for metal is already in use.

With the help of a grinder, the master makes the descent of the blade on the knife. Then follows the standard quenching procedure with oil cooling and steel tempering. After heat treatment, the master proceeds to sharpen the blade.

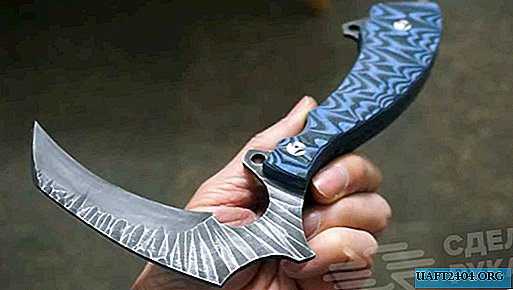

Crescent knife manufacturing step-by-step process

After sharpening on a belt grinding machine, the master makes notches on the surface of the knife (they are needed more for aesthetics). And then the knife is processed in a solution of ferric chloride and washed in a solution of soda.

At the next stage, you can begin to manufacture the handle of the knife. As a material, you can use both wood and modern composite materials (for example, mikartu or a more durable analog - fiberglass G10).

For more information on how to make a sickle knife from an old saw blade with your own hands, see the video on our website.