Share

Pin

Tweet

Send

Share

Send

Materials:

- motokosa with an unnecessary bar;

- adapter for SDS + cartridge;

- drill chuck;

- self-priming mini pump - Ali Express (//ali.pub/3iab6g);

- sheet metal;

- thick plywood or OSB;

- thin hose for supplying gasoline;

- sealed water tank;

- sprayer boom;

- hose for pump fittings;

- perforated tape.

Motor Sprayer Assembly

The pump was ordered from China by Ali Express (//ali.pub/3iab6g). It is specially designed as an attachment to an electric drill or screwdriver.

The engine of the brushcutter will be used as a power drive for the pump.

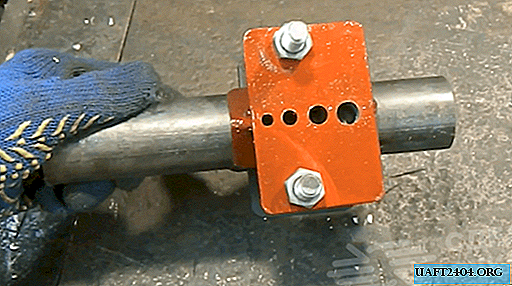

To connect them you will have to spoil the bar and the spit shaft. They are trimmed as short as possible.

An adapter on the SDS + cartridge is welded to the trimming shaft.

A drill chuck is mounted on it.

The shape of the engine of the brushcutter does not allow it to be compactly mounted. To fix this, you need to remove the tank.

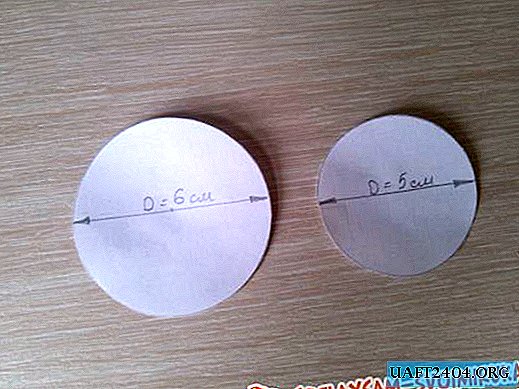

Now the motor can be fixed on a shield made of plywood or OSB. For its fastening, 2 brackets are cut out of sheet metal. They will be fixed in front on the gearbox screws and behind on the starter. Cut brackets should be welded to the sole of the same metal.

A welded strut for the engine is attached to the supporting shield and the tank clings with two bolts. Since there are now not enough native fuel line hoses from the tank to the engine, they need to be replaced with longer ones.

In the cartridge on the rod of the fixed engine, the pump shaft is clamped. The pump itself needs to be fixed by pressing it with a bracket or screws to the shield. Before this, under the pump should be trimmed boards or whetstones so that it remains in the same plane with the motor shaft.

Now you need to put a water tank on the shield.

To keep it from the same sheet metal, a shelf is cut out and bent under its bottom. The tank is mounted on a shelf and is additionally attracted by a piece of perforated tape.

Now you need to connect the inlet of the pump and the tank with a hose. The second segment of the hose is placed on the pump outlet and connected to the sprayer boom.

To be able to cling the sprayer to the back, you will need to attach the straps to the back of the shield.

The proposed manufacture of a motor sprayer can be used as a concept. This is a fairly simple whip up design. If there is an old bent headquarters from a motokosa, which is not a pity to saw, then a home-made sprayer will cost less than purchased. At the same time, the engine itself is installed and removed in a couple of minutes, so it can continue to be used on a motokosa.

Share

Pin

Tweet

Send

Share

Send