When working on a drilling machine, sometimes it is necessary to make holes in parts that cannot be clamped in a vice and put to the machine in the right way. We will solve this problem by making a simple and convenient fixture.

Please note that this homemade product also helps to avoid jamming of the drill during drilling and solves the problem of sloppy holes. For the manufacture of this homemade product we take: a metal strip, a corner, a threaded pin with twelve millimeters and nuts.

Using a band saw, we cut out the future site from the metal sheet, that is, the foundation of the structure. We make a segment about 10-15 cm in size. Next, cut from the corner of 8-10 cm. We grind the sharp parts so as not to get hurt in the future. Next task: weld the parts by placing the corner on the edge in the center of the plate.

The main stages of work

We make the upper half of the product from the same corner and plate, the dimensions are similar. The edge of the corner is polished a little for the convenience of subsequent work. We repeat the previous operation for the manufacture of the site and welding it with a corner. Then, from the pin with the m12 thread, we make two segments. We put them in order by removing the burrs.

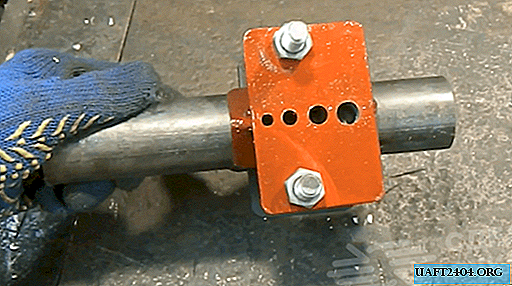

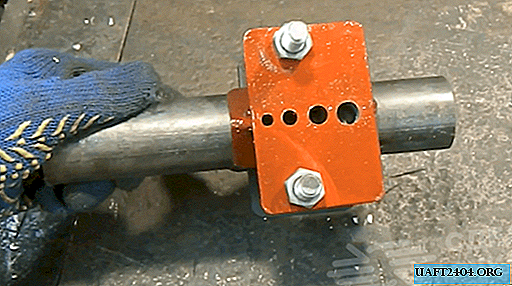

On the upper part of the device (on the site) we drill two holes along the edges. Now you need to weld the studs to the bottom of the fixture, after aligning both parts. Next, do the markup on the upper platform in the center.

We drill several through holes for the diameter of the drills, which are most often in demand in the work. After that, a simple but very useful design is ready, you can check it in action. We mark a drilling point on a pipe segment, insert it into the fixture, tighten the nuts with a wrench, and drill. The hole is clear and even!