This homemade work is noteworthy in that it is a continuation of the desktop. In addition, this movable mount is very convenient during operation and does not take up much space in the home workshop. You can make it from available materials.

The process of manufacturing a movable mount

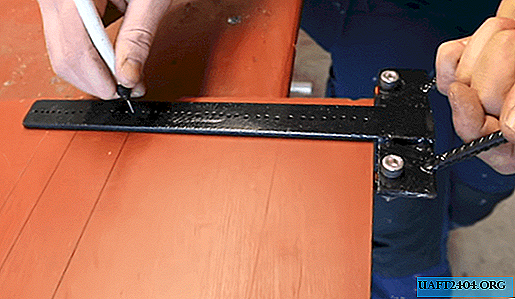

For this homemade product you will need two pieces of a profile pipe, a round pipe and a piece of sheet metal. From three pipes we weld the frame of a triangular shape. Cut to size the steel sheet in which you want to cut a small triangular hole. Then we weld a sheet of metal to the frame of pipes.

If necessary, we process the resulting metal structure with a grinding disc to remove all burrs and to clean the welds. Next, we weld a steel plate about 10-15 mm thick to the top of the triangular frame. After welding, it is also treated with a grinder.

At the next stage of work, we weld three nuts to the plate, into which we then screw a stud of suitable sizes. At the end of the stud, you must also weld a steel flat disc with holes and a nut. Then from the pipe and corner with two plates we make the last part of the structure. We connect it to the main frame of the pipes.

The final stage of work

The movable seat mount is mounted on one of the legs of a working metal or wooden table using a bolted connection. To the disk with holes you need to fasten the seat (hard or soft - at your discretion). The process of manufacturing a movable mount, see the video on our website.