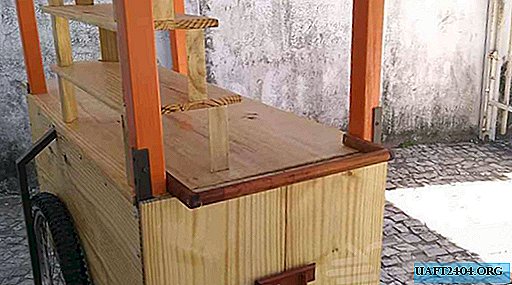

This device is not only versatile in operation, but also reliable. Thanks to a well-thought-out design, it is not inferior to factory machines: the Austrian Eisenkraft and the English MetalCraft. And in some moments even surpasses them. For example, in a homemade machine, a moving plate 12 mm thick is used, and in factory models - 10 mm.

Also, in the home-made version of the machine, an eccentric with an internal size of 60 mm is used, while in Eisenkraft and MetalCraft - 55 mm. The enlarged eccentric allows you to bend more parts at different angles. In general, for many characteristics, a homemade forging machine is better than its factory "brothers", while its cost is lower.

Design features of the forging machine

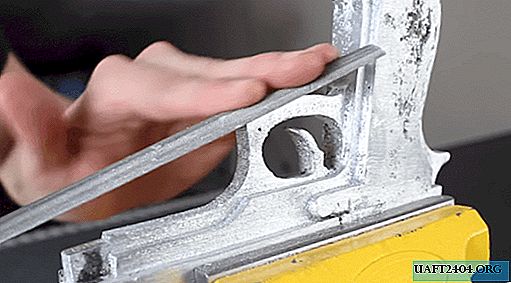

Two fixed plates are welded to the base with a thickness of 6 mm (it does not make sense to use a thicker plate, since there is no particular load on the work process). As for the fixed plates, they have a special square groove with a depth and width of 7 mm.

The side rollers of a homemade machine are made of red-hot steel of the St45 grade, and the central roller, which gives movement to the workpiece itself, is made of carbon steel of the St20 grade (using cementation). Immovable plates have a length of 180 mm, and moving - 90 mm.

The holes in the moving plates are marked individually, for a specific thickness of the workpiece. For emphasis, an M16 bolt is used here, and it is better to use M14 bolts for an eccentric. A detailed device, as well as the principle of operation of a homemade forging machine, can be seen in the video on the site.