In this article, we will tell you how to restore old rusty tongs that are used for blacksmithing at home. If the clamping lips of castor oil plants are intact, and the handles work properly (do not jam), but are “corroded” by corrosion at the ends, then it will be enough to simply replace them. This is done elementarily.

The main stages of work

First of all, we evaluate the tool visually and determine the boundaries to which the handles must be shortened. We draw the marks with a white marker and cut off the rusted parts with a grinder - and we need to cut a bit at an angle so that it can be joined with new handles.

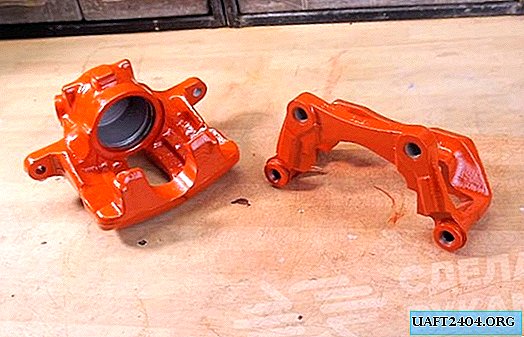

Next, you need to "soak" the ticks in table vinegar, and then clean the surface with a brush to clean the metal. Even if the tongs stuck a little, then after “bathing” in vinegar everything should work fine. At the next stage, we heat up the red steel round timber, after which we repel it on a hydraulic forging hammer, giving it a rectangular shape.

Then, we cut two handles of a suitable length from the obtained workpiece at an angle, and join them with "bits" of castor oil using welding. To make the handles monolithic, we heat the place of the welding joint red-hot and beat off with a sledgehammer on both sides. Then heat again and let cool. Next, we process the tool with a circle-brush for metal or a cleaning disk.

To summarize

As you can see, with minimal time and effort, even an old and very rusty tool can be restored. Moreover, blacksmith mites, which have lain in the earth for decades, are good because they are made of high-quality metal, and therefore will last a long time.