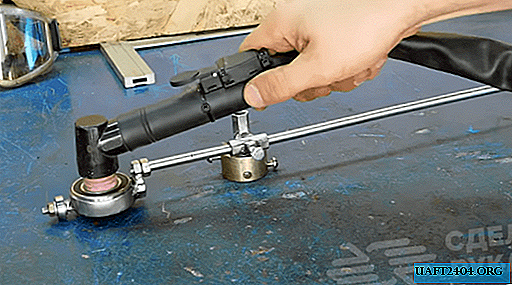

When cutting circular discs made of sheet metal with the help of a plasma cutter, it is far from always possible to ensure that the edges of the workpieces are even. As a rule, the larger the diameter of the disk to be cut with a plasma cutter, the more the arm gets tired, and, accordingly, the more likely it is to cut it crookedly.

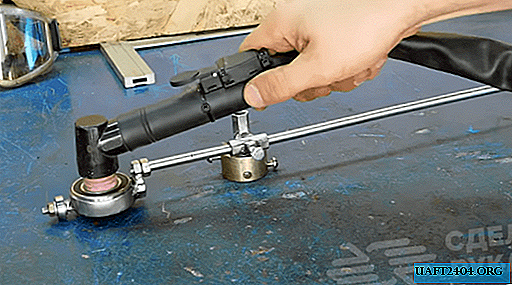

To solve this problem, you can use a homemade collapsible "compass" of bearings and a neodymium magnet. With this device, circles of sheet metal will be more even and accurate. The homemade product itself is very simple - you can make such a compass with your own hands from improvised materials.

The main stages of work

To make a compass for plasma cutting, in addition to bearings and a die holder, you will also need a piece of steel bar with a diameter of 8-10 mm, a neodymium magnet and 2 elongated nuts with a bolt.

A bearing and a neodymium magnet are inserted inside the die holder, the parts are fixed with clamping screws. In the elongated nut in the middle we drill a hole, weld a simple nut to it, and then connect it to the second long nut.

Then you need to connect the resulting part with a die holder. Next, from the bearing and improvised materials, we make a "landing socket" under the plasma cutting nozzle. In the end, it remains only to assemble all the structural elements together, after which it will be possible to begin work.

See the video on the website for the step-by-step process of manufacturing and assembling a homemade compass for plasma cutting.