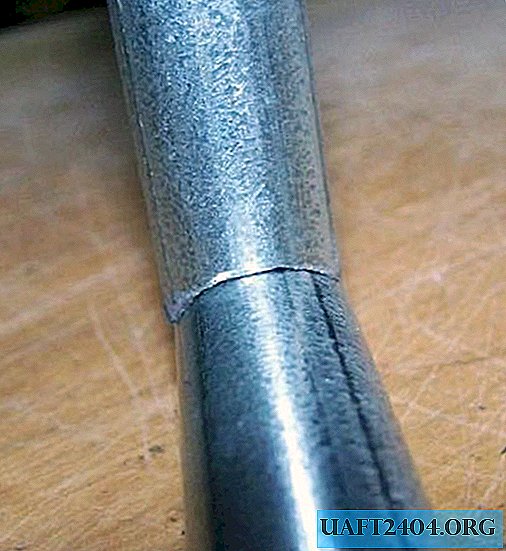

Those who are engaged in welding work at home (in the workshop or garage) often have to weld together short pieces of round pipes. Clamping workpieces in a conventional bench vise is not very convenient. Although, as an option, you can, of course.

To securely fix round pipes, a simple homemade welding fixture, which can be assembled from improvised materials, is useful.

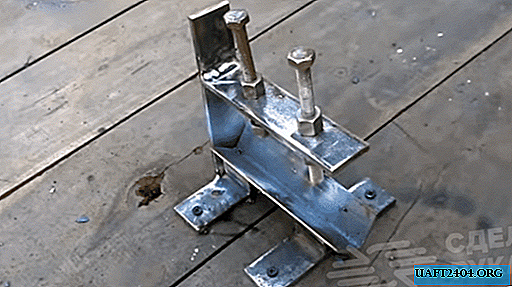

First of all, we cut two identical pieces from a steel strip 3-4 mm thick - they will be used to fasten the device itself to the surface of the table. The length of the blanks is about 12-14 cm (more, in principle, is not necessary). Drill through holes at the edges.

The main stages of work

From the profile pipe of a square section of 20x20 mm, cut two identical pieces about five centimeters long. In each of the blanks, it will be necessary to cut one wall with a grinder or drill. As a result, two U-shaped parts should be obtained from the profile.

Sections of the profile pipe are welded in the center of the metal strips. After that, cut a small piece about 15 cm long from the steel corner and weld it to the “pillows” from the profile, perpendicular to the stripes themselves.

At the last stage of work, from the remaining pieces of the strip (or other material), it is necessary to make a vertical rack on which a jumper with clamps will be located.

For more information on how to make a fixture with your own hands to fix round pipes, see the video on the website.