A simple grinding tool for use in everyday life can be made from what is at hand. In this issue we will tell you how to make a budget knife sharpener with a rotary mechanism.

This tool can also be used to sharpen another cutting tool. In general, the homemade product is quite versatile, and it can be done in literally 1 hour, using inexpensive materials.

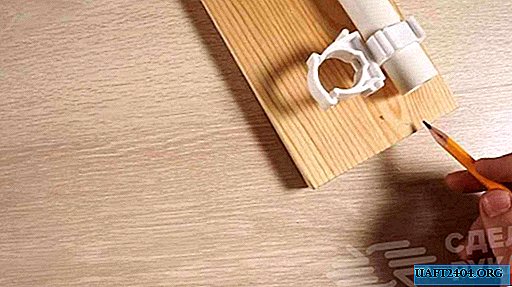

First you need a pair of clips for polypropylene pipes and an M4 screw with nut. So that the fasteners do not touch the pipe, in the clip you need to make a small hole under it (sweat). You will also need a small piece of board with a width of 120 mm.

The process of making a homemade knife sharpener

At the next stage, you need to measure the middle of the board and combine the center of the clip with the mark. You will also need to mark the center of the pipe.

Next, you will need a small piece of PVC pipe with a diameter of 16 mm to protect the cables. At an angle of 70 degrees, the master drills a hole in the board under it, stepping back a bit from the edge.

After that, it will be necessary to cut off two small rings from a polypropylene pipe with a diameter of 25 mm, and drill holes in them with a diameter of 4 mm. Then we screw in the M4 screws in them.

How to make a swivel mechanism

For the manufacture of a rotary mechanism, an M12 bolt, a profile pipe 20 * 20 mm, a segment of a polypropylene pipe and an aluminum tee are required. In the profile pipe in the center, the master drills a hole for the bolt.

As a holder for a knife, two pairs of perforated plates with a size of 40 * 80 mm are suitable (or you can use plates thicker). The swivel mechanism is mounted on the board and secured with clamps.

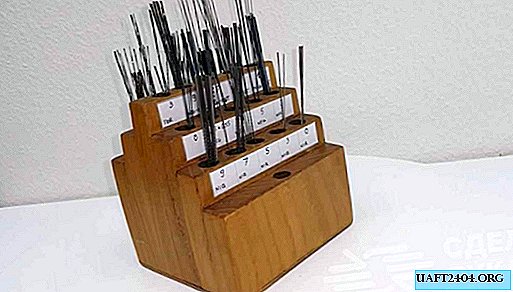

The master makes the bar for the form from a polypropylene pipe with a diameter of 16 mm. And the forms themselves are made of window glass, on the back of which sandpaper is glued to double-sided tape.