Share

Pin

Tweet

Send

Share

Send

My lawnmower had a serious problem - a hole in the gas tank formed. Having found out the price of a new tank (about 200 bucks), I decided to repair the old one, especially since I have been repairing plastic parts of medical devices for several years now and it works out pretty well for me.

In fact, most plastic products are very easy to repair, but patience, accuracy and knowledge of process technology are required. The main problem is the limited fixing time of plastic elements, therefore, in addition to theoretical knowledge, a certain skill is needed.

Thinking that my experience could be useful to other amateur masters, I decided to share this method, which can be useful for repairing various plastic parts and products.

Essential tool

To repair plastic products, a lot of tools are not required:

1. Heat gun - the main working tool with which softening of plastics is performed. A hairdryer or other heating equipment will not work, because they have insufficient power and heat flow temperature.

2. A construction knife for cutting plastics and trimming edges.

3. Steel spatula. Used to press down plastic and smooth edges.

4. A flathead screwdriver is used for the same purpose as a putty knife. A screwdriver allows you to squeeze small areas as needed.

Important! No need to use a soldering iron or any other hot object to heat the plastic.

Repair Preparation

First of all, you need to clean the product that is being repaired. I removed and washed the gas tank with plenty of running water inside and out. I also used dishwashing detergent, rags, and a stiff brush to remove all dirt. He rinsed inside until the smell of gasoline disappeared.

For the final cleaning and degreasing of the working surface, I used isopropyl alcohol. Especially successful was the fact that the alcohol bottle was made of the same plastic as my gas tank. Therefore, in order to use the bottle for making patches, it was necessary to transfer the remaining alcohol into another container.

Preparation of patches for repairs

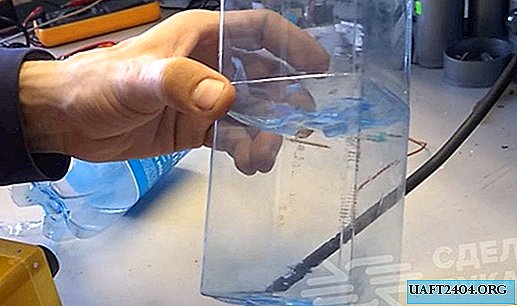

In my case, the repair was complicated by the fact that the damage was at the corner, so the patch should go around the hole on both sides. To do this, I cut a corner element from the bottle so that there was a good overlap on all sides of the hole.

You also need to remove all plastic burrs and other roughness around the damaged area so that the patch fits as tightly as possible.

Plastic overlay

The most crucial moment is the uniform and proper heating of the work area and patches. The goal is to soften the plastic and make it soft and elastic enough, but keep its shape and prevent it from spreading. It is important to observe the following rules:

- Keep the gun away from the heated part.

- Drive the heat stream over the surface of the part so that it is uniformly heated over the entire area.

- Plastic should not melt and flow, much less smoke or burn.

Softening part of the patch so that the plastic began to look wet, I put it on the repair site and began to warm it further, while smoothing and pressing the part applied to the gas tank with a spatula. As the plastic patch warms up and softens, I pressed it with a spatula so that it adheres tightly to the surface of the tank.

Advice! When smoothing a patch, it is important not to overdo it with effort, since you can push softened plastic and make it even worse than it was.

When the patch is completely glued, the parts must be allowed to cool on their own, without putting extra effort into it (do not lower into water).

Check

After cooling, I scored water in the tank to check for leaks - everything was fine, even if I pressed in the patch area.

Finally, I want to give some simple rules for the successful repair of plastic products:

- For such a "soldering" of plastic, you cannot use hot tools (soldering iron, etc.), as this will lead to the melting of the plastic and the violation of the elasticity of the material.

- The working surface and patch should be absolutely clean and degreased.

- The product to be repaired and the patch must be made of the same type of plastic. This will ensure maximum repair efficiency, as various plastics have their own temperature limit of softening and yield strength.

- It is necessary to heat gradually so that the material does not melt. If you see smoke, it means you are doing something wrong!

Note! Be prepared that the first time it may not work out and you have to impose another larger patch so that it overlaps the previous one. It may also be necessary if the plastic chosen for the patch is too thin.

Original article in English

Share

Pin

Tweet

Send

Share

Send