In this review, the author offers an easy way to connect polypropylene pipes and fittings without using a soldering iron.

This is an alternative “home” option when there is no welding iron at hand.

Please note that this method is not recommended for connecting PP pipes when installing a pressurized water supply system (for example, in a private house or apartment), since it can leak at the connection point, which can lead to unpleasant consequences.

At the same time, this method of joining polypropylene is quite suitable for the manufacture of various DIY crafts and home-made structures from PP pipes.

To connect polypropylene pipes in an alternative way, you need a gas spray gun with a burner and special scissors that are designed to cut PP pipes.

The main stages of work

For example, we need to connect two pieces of polypropylene at a right angle (90 degrees) using a corner. This can be done without using a welding iron.

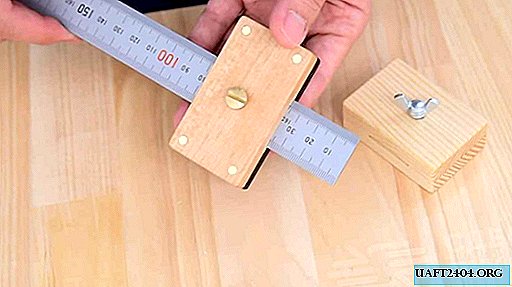

First of all, you need to measure the depth of the "seat" in the corner with a metal ruler.

Then we put a mark on the segment of the polypropylene pipe in order to understand which section will need to be warmed up.

Well, then everything is simple: we heat with a gas burner first the inner part of the corner, and then the outer surface of the polypropylene pipe.

We insert a piece of PP pipe into the corner and press for 10-15 seconds. The connection is ready!

For more details on how to connect polypropylene pipes without a soldering iron, see the video on our website.