Share

Pin

Tweet

Send

Share

Send

The industry produces a special drug, such as Calgon or another, it softens the water and minimizes the amount of solid deposits. But housewives either forget to use it in a timely manner or even refuse it because of the relatively high cost. For cleaning use old grandmother's recipes - citric acid.

How the details of the washing machine react to citric acid

There is no identical reaction, it depends on the physical and chemical properties of the materials used to manufacture the parts. The effect of acid is demonstrated by the example of three tanks of washing machines. If stainless steel does not respond to acid, then silumin treats it extremely negatively. Silumin is the most used alloy in low-cost washing machines. The chemical composition is aluminum and silicon (up to 22%), alloying additives can be added to improve physical parameters. But such technologies increase the cost of metal, which manufacturers of the cheap segment of household appliances really dislike.

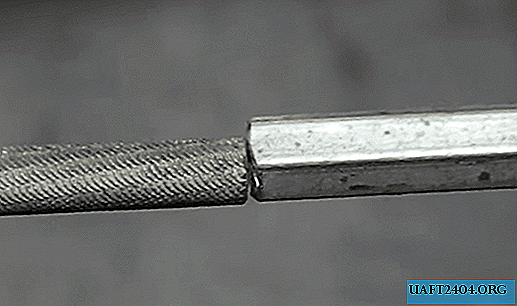

At the first stage, the metal surface is destroyed to a depth of about 1 mm, the loaded elements crack. But the machine can still work for a short time, although there is already a crack.

In the second stage, the fracture of the metal increases, cracks grow to critical sizes. Urgent repair of the washing machine is required.

The third stage is not encountered in practice, until such a state the units are not in operation. For clarity, an experiment was performed - the surface of silumin was poured with a solution of citric acid. As a result, the alloy turned into dust and completely lost its bearing properties.

By all physical and chemical characteristics, silumin occupies the last places, and its physical fatigue parameters are so low that plumbing products crack over time under the influence of very insignificant loads.

Why do manufacturers use such a weak alloy with such a "strong" name? The answer is simple: low cost, manufacturability, low weight and a very attractive name. Ordinary consumers do not know that the name includes part of the words silicon (silicon) and aluminum, but they are sure that this is evidence of the strength of the metal.

Conclusion

Professional repairmen of plumbing equipment strongly discourage the use of citric acid as a descaler for washing machines. You need to know that replacing completely failed parts always costs a lot more than saving a special tool. This is not advertising, but objective reality.

To remove unpleasant odors, it is enough to wash clothes several times a month at high temperatures - fungi and mold are destroyed.

Share

Pin

Tweet

Send

Share

Send