Share

Pin

Tweet

Send

Share

Send

Now a lot of digital technology is failing, computers, printers, scanners. Time is like this - the old is replaced by the new. But a failed equipment can still serve, although not all, but its individual parts for sure.

For example, printers and scanners use stepper motors of various sizes and powers. The fact is that they can work not only as engines, but also as current generators. In fact, this four-phase current generator is already there. And if you apply even a small torque to the engine, a significantly higher voltage appears at the output, which is quite enough to charge low-power batteries.

I suggest making a mechanical dynamo flashlight from a stepper printer or scanner engine.

Making a flashlight

The first thing to do is find a suitable small size stepper motor. Although, if you want to make the flashlight bigger and more powerful - take a large engine.

Next I need a case. I took it ready. You can take soap dishes, or even glue the case yourself.

We make a hole for the stepper motor.

We install and try on a stepper motor.

From the old flashlight we take the front panel with reflectors and LEDs. All this can of course be done by yourself.

We cut out a groove under a headlight.

Install the star from the old flashlight.

We make a cutout for the button and set it in the groove.

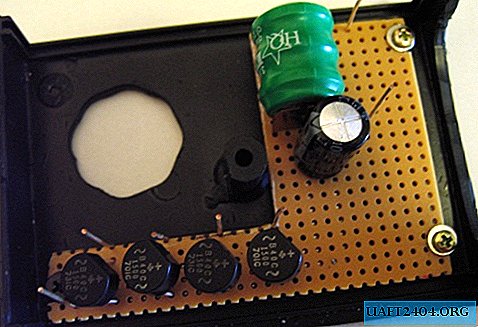

On a free site we place a board on which electronic components will be placed.

Flashlight electronics

Scheme

For the LEDs to shine, they need a constant current. The generator produces a variable, so you need a four-phase rectifier that will collect current from all the motor windings and concentrate it in one circuit.

Further, the received current will charge the batteries, which will store the received current. In principle, you can do without batteries - using a powerful capacitor, but then the glow will be only at the time of torsion of the generator.

Although there is another alternative - to use an ionistor, but it takes a considerable time to charge it.

We collect the circuit board.

All parts of the flashlight are ready for assembly.

Build Dynamo Flashlight

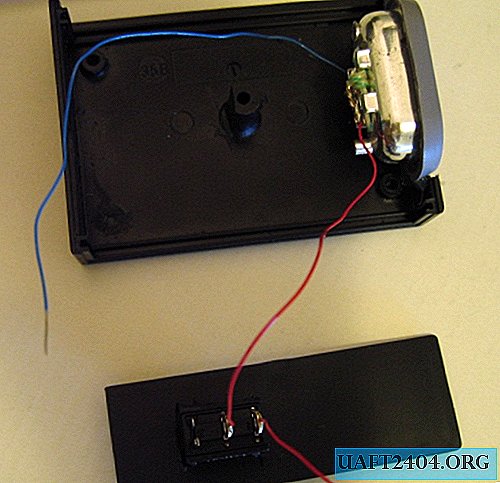

We attach the board to the screws.

We put a stepper motor and solder its wires to the board.

We connect the wires to the switch and the headlight.

Here is an almost assembled flashlight with all parts.

Completely close the case. A “G” -shaped handle is attached to the generator wheel, for which the user will rotate the engine shaft.

What does the finished flashlight look like.

That's how it shines.

Energy is enough to charge miniature batteries. The whole structure is small and fits easily in your pocket. This flashlight is good in that even after spending years without operation, it can earn again in a matter of minutes.

source

Share

Pin

Tweet

Send

Share

Send