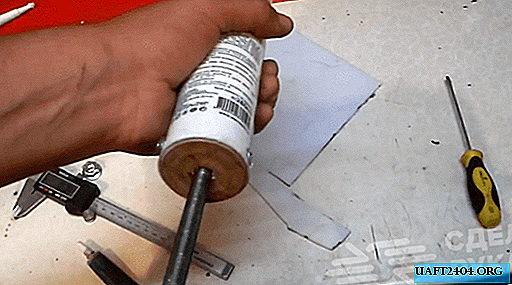

To make the extension cord, you will need a steel bar and an old head with a whole input part (side with a quadrangle). The main part of the extension cord is selected from good steel so that the tool can withstand the load.

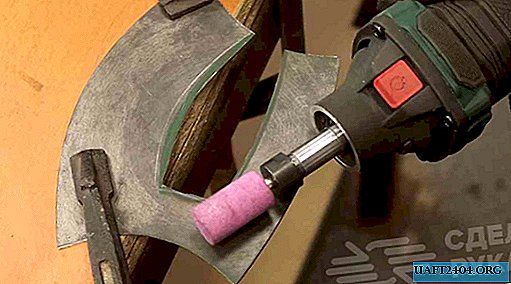

If the head is simply scalded at one end of the bar, then the second end will have to be worked out more carefully. The other side is adjusted manually, the main thing is not to weaken the landing size. And as on a factory tool, a ball with a spring is installed on the tetrahedron.

If the head is simply scalded at one end of the bar, then the second end will have to be worked out more carefully. The other side is adjusted manually, the main thing is not to weaken the landing size. And as on a factory tool, a ball with a spring is installed on the tetrahedron.

The advantages of a homemade extension cord are that old pieces of iron are used for its manufacture and the size of the tool is made for any needs.