This device is very easy to make yourself from improvised materials, so it is a worthy alternative to ordinary store clamps. To make such a universal clamp, you need a small piece of steel bar with a diameter of 8 mm, as well as a pair of M10 nuts.

Manufacturing process

Using a grinder or an ordinary hacksaw for metal, two workpieces 12 cm long must be cut from a piece of steel bar - they must be welded to each other (it is enough to make a weld of 1-2 cm on both sides).

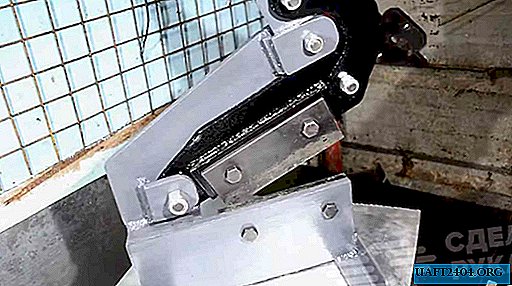

After that, you need to expand the middle of the "paired" workpiece with a chisel. The edges of the product must be sharpened with a grinder, and on one of the sides - make another shallow cut. Two M10 nuts must be welded vertically in the center of the workpiece.

When both nuts are securely welded, they need to stick the rest of the steel bar with a diameter of 8 mm, measure the distance from the edge of one nut to the edge of the other, make a longitudinal cut with a grinder and bend the bar with the letter "G". Then you need to cut off the excess part from the bar.

Clamps pluses

A homemade device for tightening clamps, in addition to low cost, has other obvious advantages: it is quite easy and convenient to work with, and this device is lightweight and compact in size.

But the most important thing is that the device is universally applicable. With this clamp you can make clamps from wire, as well as from thin steel strips. See the video for a step-by-step process of manufacturing this device.