To replace old worn bearings or simply remove them from the motor shaft, special devices are used - pullers. The stores offer a variety of models to choose from: from compact to stationary. But why overpay when you can make a bearing puller with your own hands from improvised materials?

For the simplest mechanical puller, you will need: a bottle-type hydraulic jack, two pieces of a channel and two long studs with nuts, which will be used as guides. If there is no channel at hand, it can be found without problems at the scrap metal collection points.

The main stages of work

To make a home-made mechanical puller, you need two identical sections of a channel approximately 30-40 cm long (if necessary, you can take larger pieces). Having left 4-5 cm on each side, it is necessary to drill holes in the "sole". For greater accuracy, it is better to do this on a drilling machine.

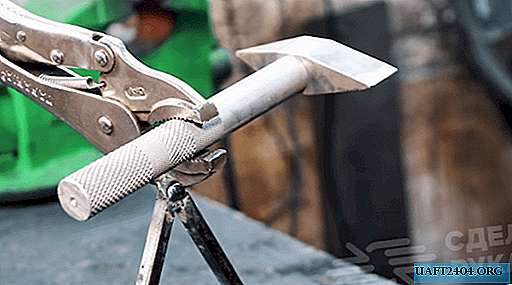

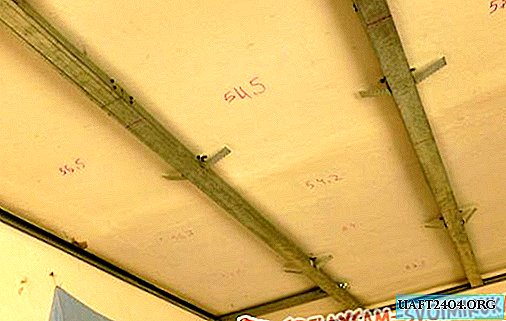

In one channel, you need to drill a hole in the center, and then use a grinder to cut a wedge. Next, two prepared sections of the channel, stripped of rust, are connected using studs and rigidly fixed with nuts. A hydraulic bottle jack is installed between them.

Now the home-made mechanical bearing puller is fully assembled and ready to go. If desired, the metal surface can be painted with spray paint from a spray can. If something is not clear, watch the video, which clearly demonstrates the whole process of manufacturing a mechanical puller from a jack.