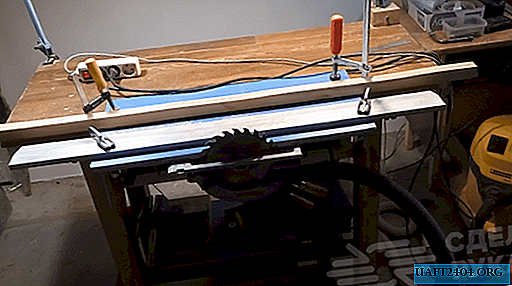

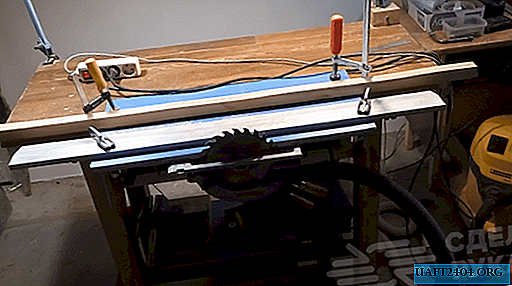

Sometimes there are situations when you need to urgently dissolve an unedged board on the bars, and at hand only a manual circular. In this case, you can make a temporary sawing table using improvised materials for this. For example, a suitable piece of particleboard, OSB or plywood with a thickness of at least 20 mm.

Such a sawing table is assembled quickly enough, because you do not need to perform any calculations, make markings, cut a hole in the center of the table and build a frame. Everything is much simpler - that's why the table is called temporary, because in haste.

We attach a circular to a piece of chipboard or plywood, set the necessary gap between the saw blade and the edge of the table, after which we mark and drill four holes for the bolts, with which the manual circular will be attached.

The main stages of work

After we have drilled the holes, we again apply a circular to the edge of the chipboard, and fix it with bolts and metal corners. We place wooden wedges at the corners to make an effort to press.

Moreover, the wedge itself should be directed in the opposite direction from the circular itself. This is necessary so that they do not jump out of vibration during operation.

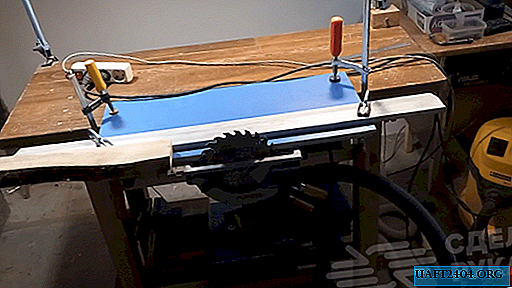

At the last stage, we turn the sheet of chipboard and fix it to the table or workbench using two F-shaped clamps at the edges. After that, we expose the guide from the aluminum rule for construction work.

The design is very simple, which is why it is unsafe, so you need to be very careful. For a detailed table assembly process, see this video.