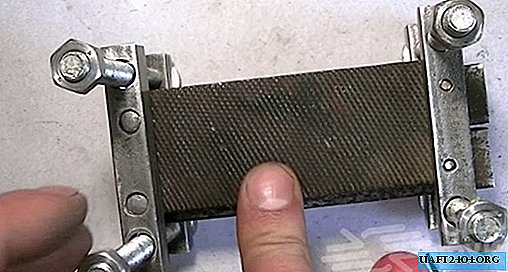

The author is sure that with the help of this home-made tool "3 in 1" it is very convenient to process various metal billets in a home workshop or garage. And to make such a homemade product is very simple: this will require two plates, two studs and nuts.

What can be done with this device? It is possible to fix round pipes for the purpose of their subsequent cutting or grinding. Also, for the same purpose, homemade makes it possible to quickly clamp wider workpieces - for example, metal plates or strips.

In addition, this device makes it possible to fix round pipes or rods in order to drill holes in them. In general, as you can see, the scope of this homemade product is really wide.

The main stages of work

First of all, it is necessary to cut off two pieces of a plate 70 mm wide - these will be the main materials for the manufacture of a universal device. The length of each plate is 15 cm.

In one of the plates, which will be the base of the homemade product, you need to drill four through holes in the corners. They are needed to attach the plate to the surface of the table.

Further, in each plate, the author drills two more holes along the edges - they will install the hairpin segments. Three different holes are drilled in the center plate in the center. Then a large nut is welded.

At the last stage of the work, the master performs painting of the main parts, as well as assembling the homemade product. For details on how to make a universal device for processing metal blanks, see the video on the website.