From the old file for metal, the master decided to make a universal nozzle for a network electric drill. Also, this device can be used in conjunction with a cordless screwdriver.

The main purpose of this nozzle is to chamfer the outside and inside of the pipe. But the master also uses this tool to drill holes in wooden workpieces. Only the nozzle installs already in the drill chuck.

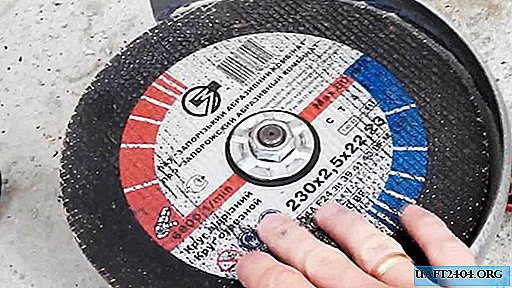

First of all, the master cuts off two pieces of a length of about 5-7 cm from the old flat file for metal. Then you also need to make triangular cuts in the blanks with a grinder.

The process of making a nozzle for a drill

At the next stage, the master makes cutting edges on the "teeth" of the workpieces. Then one of the parts of the file must be cut in half along. And then all the parts are welded together. The result should be a crown.

The master welds a “shank” to the back of the crown, so that the nozzle can be inserted into the drill chuck or screwdriver.

In the end, it remains only to clean the welds with a grinder, and the homemade nozzle is ready for work. Of course, its use at home is a big question, but the master believes that such a thing can come in handy.

Details on how to make a universal drill head from an old file can be found in the video on the website.