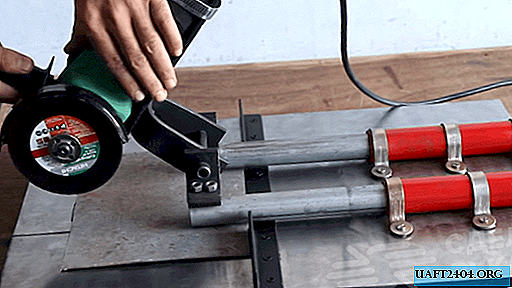

You can weld a profile pipe at a right angle in several ways, depending on what result you want to get.

In this review, the author shows three different ways of connecting a profile pipe at 90 °. Take note.

The first way is the easiest. It is necessary to cut off two pieces of a profile pipe. We join them at a right angle, grab, and then scald.

With this method of connecting the profile pipe, one end remains open. It can be brewed with a steel plug or simply corked with a wooden block.

Two more ways to weld profile pipes

The second method is interesting in that with such a connection there will be no "open" end.

Cut two pieces at an angle of 45 degrees. We clean the edges of the profile pipes with a grinder, after which we grab, check if there is a right angle, and scald.

The third method is a bit more complicated. We cut two pieces of the profile pipe. From the third segment cut a piece of a triangular shape.

Then we join the two blanks with each other using a triangular piece. We grab and scald. We clean the welds with a grinder.

You can see more details about the three ways of connecting a profile pipe at 90 ° in the video on our website.