To reliably tighten the wire clamp (for example, to fix the rubber or silicone hose on the water pipe in the country), you will not do with ordinary pliers or pliers. A more convenient and practical tool is required.

To do this, you can make a simple home-made clamp from a piece of polypropylene pipe and a window handle, which will help to cope with this task.

First of all, it is necessary to cut a piece of PP pipe of suitable length. Dimensions in this case can be arbitrary. Take, for example, a length of 15 cm. Also for this homemade product you will need an old Soviet-style window handle and a piece of round steel pipe. Now we begin to manufacture a homemade clamp.

The main stages of work

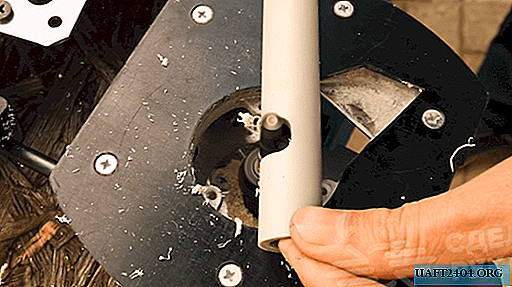

In a polypropylene tube with a length of 150 mm, a small groove must be made. To do this, you can use the cutter. If there is no manual milling cutter at hand, you can go the other way. First we drill 2-3 holes, and then we expand the groove to the required size with a file.

Polypropylene lends itself very well to mechanical processing, so this operation will not take much time. Then we take a piece of metal pipe and flatten one edge with a hammer. Next, we take in our hands an angle grinder with a cutting disc and make small cuts on the flattened side of the pipe.

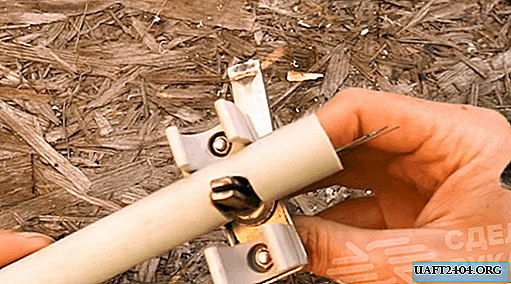

Then we heat the edge of the steel tube with a gas burner, and then insert it into a piece of polypropylene pipe. At the last stage, we make a grinder a longitudinal cut in the steel square core of the window handle. And then we attach two more clips for plastic pipes to it.

This device is very far from the clamp of lawyer Egorov, but, as an option, it is quite possible to use. The detailed process of manufacturing a homemade clamp from a polypropylene pipe and a window handle can be seen in the video on the website.