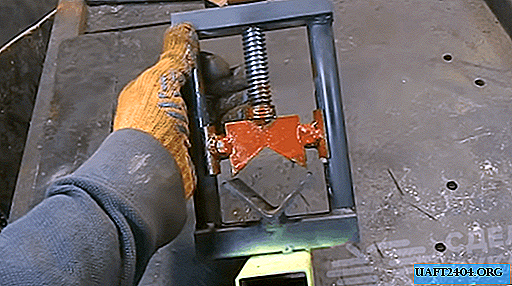

Convenient and practical to use, a tube vise made from improvised materials will be useful in any home workshop. Thanks to its design, home-made tube vices securely clamp round metal pipes, as well as cylindrical parts. They can also fix profile pipes if necessary.

When you need to cut a thread on a cylindrical workpiece or cut a piece of a round pipe, then ordinary metalwork vice do a poor job. The pipe strives to constantly twist between the flat clamping jaws. But the tube vise is perfect for this job.

For this home-made device you will need a half-inch pipe, a three-quarter pipe length, a profile of 50x30 mm, a profile of 40x25 mm and a profile of 20x30 mm. In addition, it will be necessary to find a sheet of metal about 10 mm thick. A screw is required to control the pressure jaw.

The main stages of work

The manufacturing process of home-made tube vices begins with the body. For this, a piece 12 cm long must be cut from a profile pipe 5030 mm. A piece 13 cm long will need to be cut off from a 40x25 mm profile. We cut a third segment 130 mm long from a 30x20 profile.

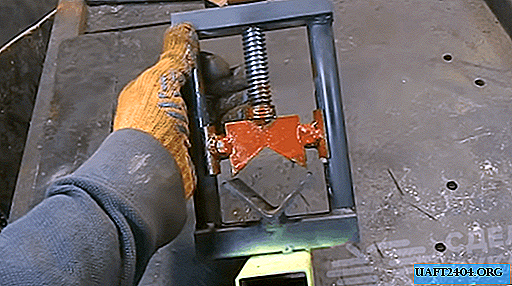

From the half-inch pipe we cut two pieces 16 cm long. Then we connect all the parts together. First, at the edges of the 40x25 mm profile, two pieces of a half-inch pipe should be welded. Well, then in the profile pipe 30x20 it is necessary to drill a through hole with a diameter of 20 mm.

At the next stage, we weld the frame with the base of the device. For details on how to make a practical tube vise from improvised materials, see the video