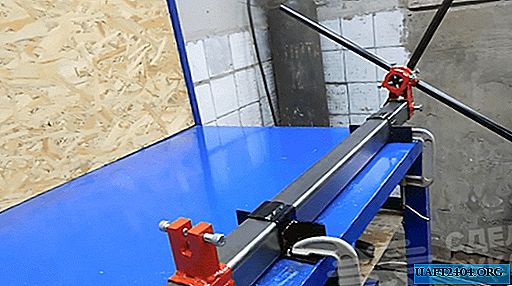

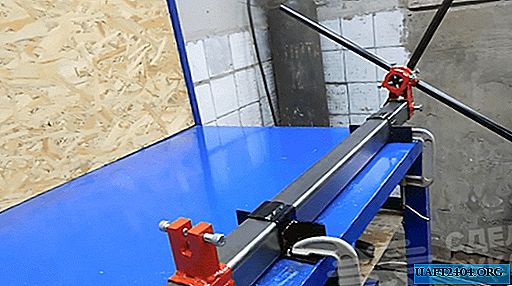

A twisted square bar (torsion bar) will decorate any forged product. However, twisting the square yourself, without special tools, is quite difficult. It does not always turn out to be beautiful and uniform twisting.

This can be done with a hand machine, which is easy to assemble in a garage or home workshop. To make the device with your own hands, you will need the most ordinary materials - these are loops, several cutters, die holders, washers, bearings and a profiled pipe.

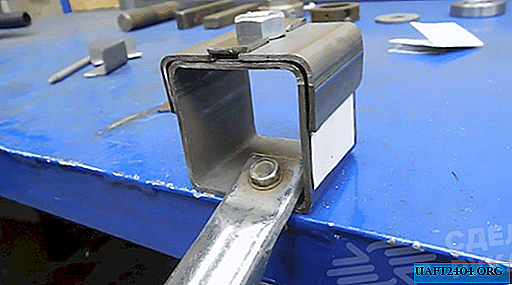

First of all, we cut 4 segments of the trade union pipe. On one segment we make markup and cut it into corners. Then we take one piece of pipe and attach 2 corners from above, fastening them with plates, a nut and welding. It turned out to be a case, on two opposite sides of which there are holes from the nuts for fixing.

Work Stages

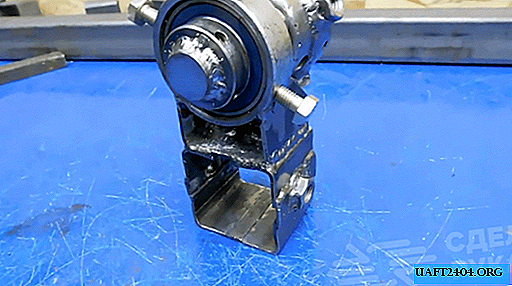

From another section of the profile pipe, it is necessary to cut out the support for the holder. The holder itself, mounted in a support, is also supported by “amplifiers” from the cutter. Then we weld the parts and clean them. In another holder, we drill a pair of holes in the end, to which 4 nuts need to be welded.

We put the parts together, join and weld. Install the bearing in the holder. Then install the second part. It will rotate on the part of the loop that needs to be passed through the bearing, and weld to the body of the second part.

Next we will make another holder, which we weld to the body. In the process, we cool the welding spot due to the close proximity of the bearing.

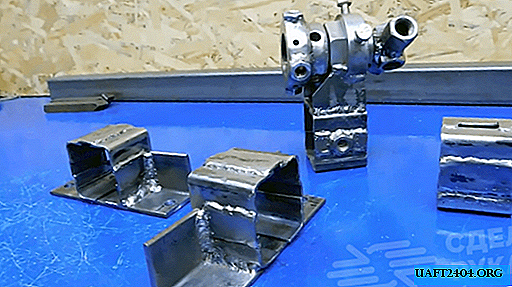

We make long of several nuts, for this we weld 4 nuts together. The result was a design of three in the middle and two on the side. Due to heavy loads, it is necessary to boil everything well.

Then we make 3 more squares from the corners and plates. It is important that they move freely along the main pipe. We also weld corners to the squares on both sides, in which holes are made for mounting on a work surface.

From cutters we make stops for the machine. Divide them by 3: two, equal in length, and one smaller. We drill a hole in the segments and cut the threads for the bolts.

Then we weld these 3 incisors to each other: between 2 large we have a small incisor. Grind the seams. The part is welded to the square. We screw bolts into the holes. It turns emphasis for the rear of the machine.

We cut the hairpin into 4 segments. Also, just cut a pipe that fits the size just a little longer. We stick the tip of the stud sticking out of the pipe and weld it with the pipe. It turns out 4 handles. Before painting, degrease the parts, then prime and paint. We collect all the details on the pipe - we get a machine, which we strengthen on the desktop.