Have you ever tried to connect a copper wire using electric welding? Be sure to try - this connection is the most reliable and durable.

In this review, the author clearly shows the welding process of a copper welding cable with a cross section of 25 squares.

We take two pieces of cable that need to be connected. We remove the insulation at the ends, and then we twist and fix the joint in the usual bench vice.

The main stages of work

To weld a copper cable using electric welding, we need a homemade electrode from a graphite brush and a bit of borax.

As for the current strength, we set it approximately within 50 Amps. Polarity is direct (we throw a negative contact on the holder).

Sprinkle the copper twist with brown (ideally, you first need to heat the copper with a gas burner), after which you can start the welding process.

You can, of course, do without borax, but it is better with it, since in this case copper is much less oxidized during welding.

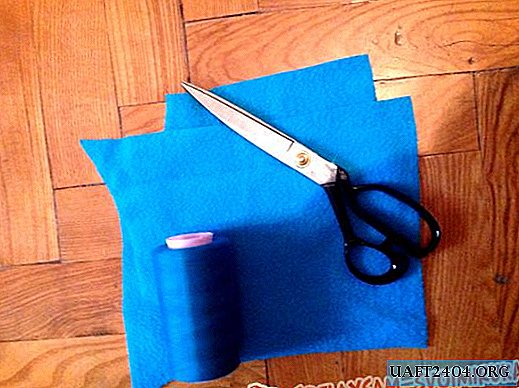

After our connection is welded, isolate it with tape (preferably blue) or heat shrink.

For details on how to connect a copper cable by welding, we recommend that you watch in the video on the site.