Share

Pin

Tweet

Send

Share

Send

The circuit of voltage converters is a sea, but as a right after assembly there are defects, malfunctions, incomprehensible overheating of individual parts and parts of the circuit. The assembly of the converter took me two weeks, because a number of changes were made to the main circuit, as a result, I can safely say that it turned out to be a powerful and reliable converter.

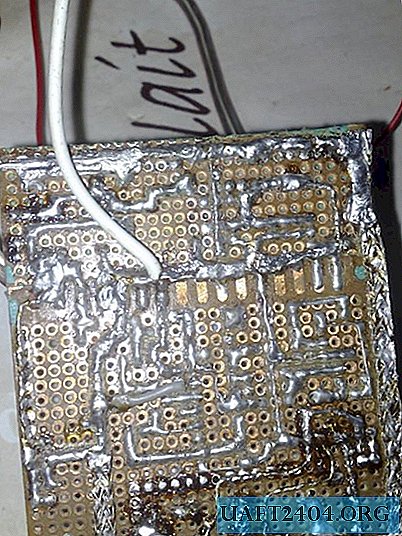

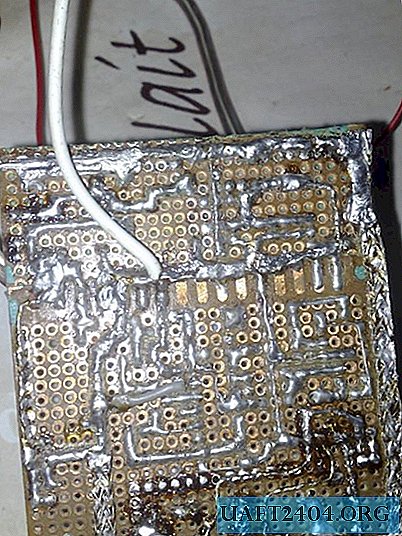

The main task was to build a 300-350 watt converter for powering the amplifier according to the Lanzar scheme, everything turned out beautifully and accurately, everything except the circuit board, we have a large deficit in the chemistry for etching the circuit boards, so I had to use a breadboard, but I do not advise repeating my torment, soldering wiring for each track, tearing every hole and contact is not an easy job, you can judge this by looking at the board from the back. For a beautiful appearance, a wide green adhesive tape was glued to the board.

PULSE TRANSFORMER

The main change in the circuit is a pulse transformer. In almost all articles of homemade subwoofer installations, the transformer is made on ferrite rings, but the rings are sometimes not available (as in my case). The only thing that was was an alsifer ring from a high-frequency inductor, but the working frequency of this ring did not allow using it as a transformer in a voltage converter.

Here I was lucky, almost for nothing I got a couple of computer power supplies, fortunately in both units were completely identical transformers.

As a result, it was decided to use two transformers as one, although one such transformer can provide the desired power, but when winding the windings, they simply would not fit in, so it was decided to redo both transformers.

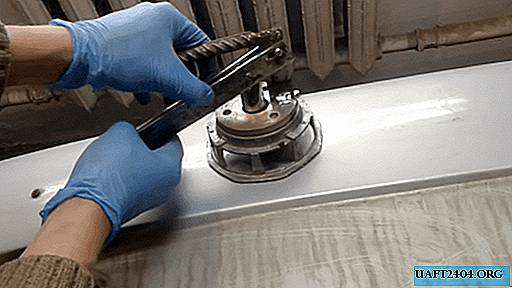

In the beginning, you need to remove the hearts, in fact, the work is quite simple. Lighter heat a ferrite stick, which closes the main hearts and after 30 seconds of hot glue melts and the ferrite stick falls out. The properties of the stick may change from overheating, but this is not so important, since we will not use the sticks in the main transformer.

We do the same with the second transformer, then remove all standard windings, clean the terminals of the transformers and cut off one of the side walls of both transformers, it is desirable to cut off the contact-free wall.

The next part of the work is gluing frames. The fastening place (seam) can simply be wrapped with tape or tape, I do not advise using a variety of adhesives, as this may interfere with the insertion of the core.

I had experience in assembling voltage converters, but nevertheless this converter survived all the juice and money from me, because during the work 8 field workers were killed and the transformer was to blame.

Experiments with the number of turns, winding technology and wire cross-section led to encouraging results.

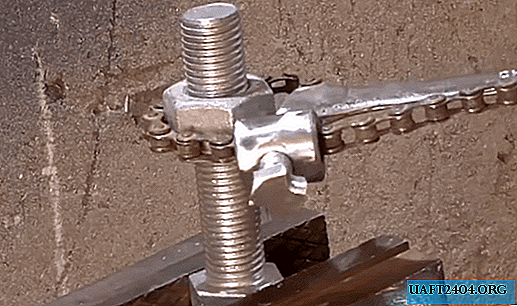

So the hardest thing is winding. Many forums advise winding a thick primary, but experience has shown that a lot is not needed to get the indicated power. The primary winding consists of two completely identical windings, each of them is wound with 5 wires of 0.8 mm wire, stretched along the entire length of the frame, but we will not rush. To begin with, we take a wire with a diameter of 0.8 mm, the wire is preferably new and flat, without bends (although I used the wire from the network winding of the same transformers from the power supplies).

Then along a single wire we wind 5 turns along the entire length of the transformer frame (you can also wind all the wires together with a bundle). After winding the first core, it needs to be strengthened by simply screwing it onto the side leads of the transformer. After already we wind the rest of the veins, smoothly and accurately. After the end of the winding, you need to get rid of the varnish coating at the ends of the winding, this can be done in several ways - to heat the wires with a powerful soldering iron or to peel the varnish separately from each wire with a mounting knife or razor. After that, you need to tear the ends of the wires, weave them into a pigtail (it is convenient to use pliers) and cover them with a thick layer of tin.

After that, we move on to the second half of the primary winding. It is completely identical with the first one, before its winding we cover the first part of the winding with electrical tape. The second half of the primary winding is also stretched along the entire frame and wound in the same direction as the first, we wind along the same principle, one core.

After winding is complete, the windings must be phased. We should get one winding, which consists of 10 turns and has a tap from the middle. It is important to remember one important detail - the end of the first half should join with the beginning of the second half, or vice versa, so that there is no difficulty in phasing, it is better to do everything from photographs.

After hard work, the primary winding is finally ready! (you can drink beer).

Secondary winding - also requires a lot of attention, since it will be it that will power the power amplifier. It is wound on the same principle as the primary one, only each half consists of 12 turns, which completely ensures a bipolar voltage of 50-55 volts at the output.

The winding consists of two halves, each wound with 3 veins of 0.8 mm wire, the wires are stretched throughout the frame. After winding the first half, isolate the winding and wind the second half over in the same direction as the first. As a result, we get two identical halves, which are phased in the same way as the primary. After the findings are cleaned, braided and sealed to each other.

One important point - if you decide to use other types of transformers, then make sure that the halves of the heart do not have a gap, as a result of experiments, it was found that even the slightest gap of 0.1 mm dramatically disrupts the operation of the circuit, the current consumption increases 3-4 times , field effect transistors begin to overheat so that the cooler does not have time to cool them.

The finished transformer can be shielded with copper foil, but it does not play a particularly large role.

The result is a compact transformer that can easily deliver the right power.

DIAGRAM

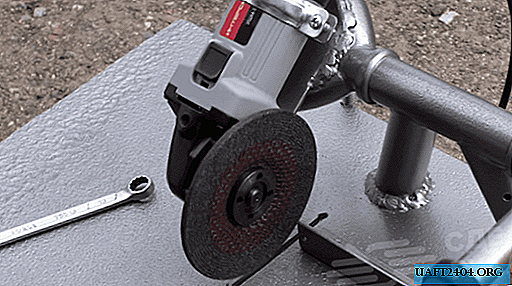

The device diagram is not simple, for beginner hams I do not advise you to contact him. The basis, as always, is a pulse generator built on the TL494 integrated circuit. An additional output amplifier is built on a pair of low-power transistors of the BC 557 series, an almost complete analogue of the BC556, KT3107 can be used from the domestic interior. As power keys, two pairs of powerful field-effect transistors of the IRF3205 series were used, 2 field poles per shoulder.

Transistors are installed on small heat sinks from computer power supplies, pre-isolated from the heat sink with a special gasket.

A 51 ohm resistor is the only part of the circuit that overheats, so the resistor is needed for 2 watts (although I only have 1 watts), but overheating is not terrible, this does not affect the operation of the circuit.

Installation, especially on a breadboard, is a very boring process, so it's best to do everything on a printed circuit board. We make the plus and minus tracks wider, then cover them with thick layers of tin, since considerable current will flow through them, the same with the drains of field workers.

We put 22 ohm resistors at 0.5-1 watts, they are designed to remove overload from the microcircuit.

Polevik gate current limiting resistors and microcircuit supply current limiting resistor (10 ohm) are preferably per half watt, all other resistors can be 0.125 watts.

The frequency of the converter is set using a 1.2nf capacitor and a 15k resistor, by decreasing the capacitance of the capacitor and increasing the resistance of the resistor, you can raise the frequency or vice versa, but it is advisable not to play with the frequency, since the operation of the entire circuit may be disrupted.

Rectifier diodes were used by the KD213A series, they coped best of all, because of the operating frequency (100 kHz) they felt fine, although you can use any high-speed diodes with a current of at least 10 amperes, it is also possible to use Schottky diode assemblies, which can be found in the same computer power supplies, in one case 2 diodes that have a common cathode, so for the diode bridge you will need 3 such diode assemblies. Another diode is installed on the circuit power, this diode serves as protection against power overload.

Capacitors, unfortunately, I have a voltage of 35 volts 3300 microfarads, but the voltage is better to choose from 50 to 63 volts. On the shoulder are two such capacitors.

The circuit uses 3 chokes, the first to power the converter circuit. This choke can be wound on standard yellow rings from power supplies. Evenly around the ring we wind 10 turns, a wire in two cores of 1 mm.

Inductors for filtering RF interference after the transformer also contain 10 turns, a wire with a diameter of 1-1.5 mm, are wound on the same rings or on ferrite rods of any brand (the diameter of the rods is not critical, the length is 2-4 cm).

The power to the converter is supplied when the Remote Control (REM) wire is closed to plus power, this closes the relay and the converter starts to work. I used two relays connected in parallel at 25 amperes each.

The coolers are soldered to the converter unit and turn on immediately after turning on the REM wire, one of them is designed to cool the converter, the other is for the amplifier, you can also install one of the coolers in the opposite direction, so that the latter removes warm air from the common case.

RESULTS AND COSTS

Well, what can I say, the converter met all the expectations and costs, it works like a clock. As a result of experiments, he was able to give an honest 500 watts and could have done more if the diode bridge of the unit that the converter was supplying had not died.

In total, the converter was spent (prices are for the total number of parts, not for one)

IRF3205 4pcs - $ 5

TL494 1pc -0.5 $

BC557 3pcs - 1 $

KD213A 4pcs - $ 4

Capacitors 35v 3300mkf 4pcs - 3 $

Resistor 51ohm 1pc - $ 0.1

Resistor 22ohm 2pcs -0.15 $

Development Board - $ 1

From this list, the diodes and capacitors were in vain, I think except for field workers and microcircuits everything can be found in the attic, ask friends or in workshops, so the price of the converter does not exceed $ 10. You can buy a ready-made Chinese subwoofer amplifier with all the amenities for $ 80-100, and the products of well-known companies cost a lot, from $ 300 to $ 1,000, in return you can assemble an amplifier of the same quality for only $ 50-60, even less if you know where to get the details I hope I could answer many questions.

AKA KASYAN

Share

Pin

Tweet

Send

Share

Send