Share

Pin

Tweet

Send

Share

Send

What is needed

The main part (center punch) is made of the inlet valve of the engine (it has a larger diameter than the exhaust). The valve moves along the front wheel hub of the bicycle. For the convenience of the punching process, two springs were used, the diameter and length are selected taking into account the dimensions of the valve leg and the parameters of the sleeve, all parts are fixed with a washer on welding.

Core technology for long work

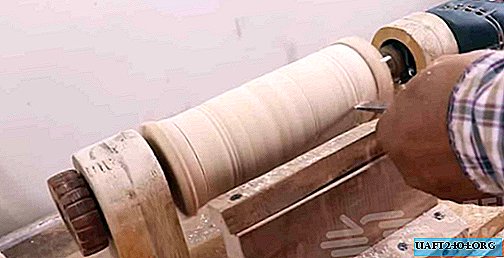

Fix the grinder with the grinding disk in a vise in a horizontal position, fix it carefully, do not damage the plastic tool case. Sharpen the valve tip under the cone. Make its top as sharp as possible. The stem is made of especially strong alloy steels, sharpen slowly, do not allow metal tempering.

Use WD to clean the bike axle of dirt and old oil. Check the completeness and dimensions of the parts: two springs, a washer, a valve and the front axle of the wheel. The washer should fit easily onto the stem.

Put one spring on the valve, insert it into the axle.

On the reverse side, install the second, squeeze it a little and put the washer on top.

In this position, it is necessary to fix all the parts of the device.

To do this, place the valve with the lower spring and axle on the guide of the movable jaw. Squeeze the lower spring until the upper one falls below the groove of the valve retainer and in this position clamp the vice.

Install the washer on the spring in height just below the groove. Grab parts in several places.

Scale the weld and allow time to cool. As we mentioned above, do not overheat the metal, otherwise crystallization will change, it will become soft and unsuitable for coring.

The device is ready, test its performance.

Make a few marks on the round pipe and metal strip.

Check the condition of the core. If it is not dull - everything is fine, you can use the device for its intended purpose.

Conclusion

If there are no old valves, no problem. Instead, you can use any improvised products from red-hot steel: files, axes of special mechanisms, etc. Are not sure of their strength - before starting work, make several marks for the sample.

Share

Pin

Tweet

Send

Share

Send