Share

Pin

Tweet

Send

Share

Send

Materials:

- steel strip 5 cm wide;

- 3 washers M8;

- 2 short bolts M8 with nuts;

- long bolt M8;

- elongated nut M8;

- tube with an inner diameter of 9-10 mm.

Crimp Making

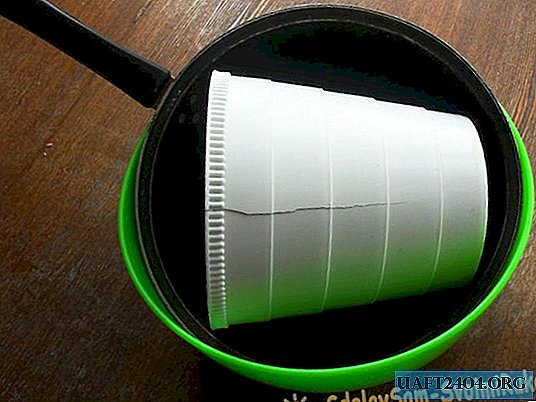

The working part of the tool will be made of a steel strip 5 cm wide. A piece is taken literally 15 cm long and is drawn as in the photo.

It will be dissolved along 2 sponges, between which you need to make holes for different diameters of the tips. In the example there are 2, but it is better to immediately grind all the popular sizes.

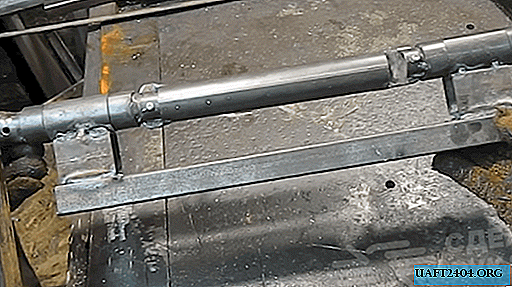

The cut workpiece is opened in half using a thin cutting disc.

After that, you need to grind the holes between the jaws to get the contact part of the crimp. To do this, it is better to use a grinder, not a drill, since the cutouts should be angular, and not round.

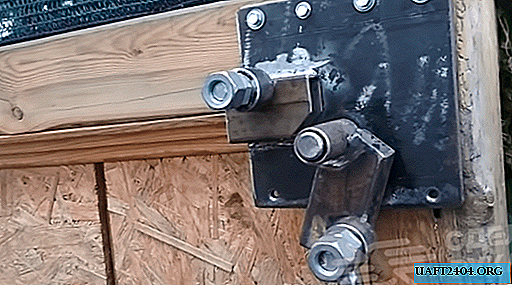

To connect the workpieces together after receiving the mites, you need to make eyes on them. To do this, a washer is digested for each sponge, after which they are attracted together with a bolt and nut.

A hole is drilled on the protrusion of the elongated tool lip to which a modified bolt is screwed with a welded washer instead of the head.

A piece of tube is welded onto the second sponge.

To obtain a mechanism for tightening the jaws, a bolt with a washer instead of a cap is fixed on the bottom of the guillotine and passed through a tube on the second sponge. An elongated nut with a welded handle is screwed onto it. The wide nut has an enlarged stop area in the thread, so it does not break under pressure.

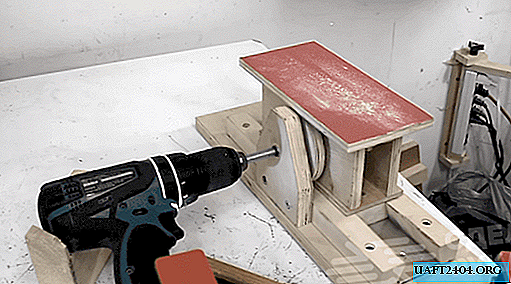

To use the tool, it is necessary to insert a stripped wire with a tip between its pincers.

Rotating the elongated nut with the handle, you need to squeeze his lips, thereby deforming the tube.

To increase the contact area, crimping is done several times in increments of a couple of millimeters. When using a powerful tube, when large efforts are required for deformation, you can rotate the nut with a wrench.

Assembling such a crimp will cost a penny, while it compresses the tips much more accurately than a vice or pliers, although it does not reach the real crimper.

Share

Pin

Tweet

Send

Share

Send