Share

Pin

Tweet

Send

Share

Send

The main materials:

- electric motor (as an option, it is quite possible to take from a washing machine);

- plywood 15-20 mm;

- double sided tape;

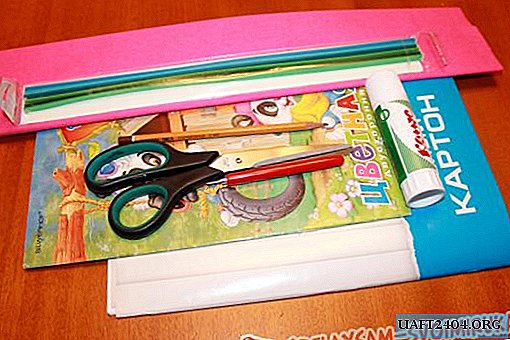

- sandpaper;

- sewer pipe 50 mm;

- epoxy adhesive;

- wood glue;

- self-tapping screws.

Machine tool

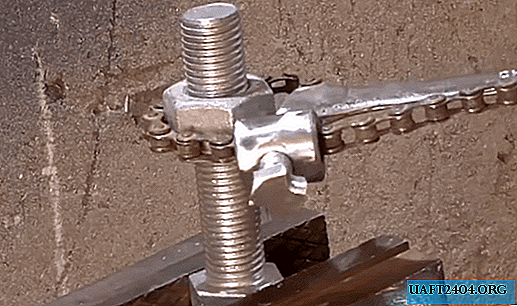

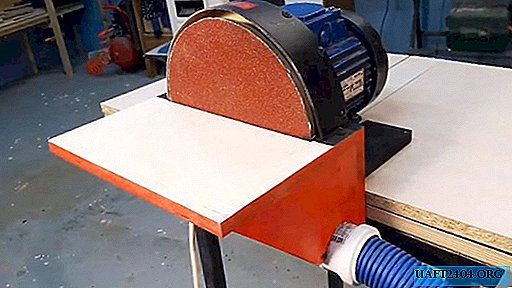

The proposed design of the machine is adapted to the device of the motor housing from the pump station or compressor. The main condition is the presence in its front of the mounting plate.

A disk with a diameter of 230 mm is cut out of plywood for attaching sandpaper.

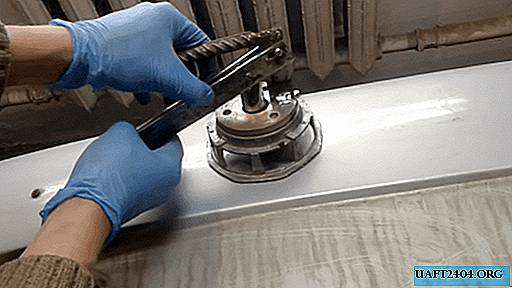

To fix it on the motor shaft, a faceplate is made. Her body is cut out of plywood. The faceplate is fixed to the center of the circle with wood glue and self-tapping screws.

Using epoxy, a flange from the motor shaft is glued into it.

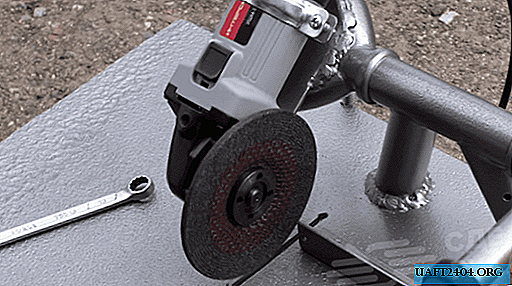

After the epoxy glue hardens, the disk is mounted on the motor shaft and is already turned on it with sandpaper under a perfect circle.

To make a stand for the supporting table, a plywood sheet is applied to the front mount of the motor, circled around the upper circumference and cut out.

On its sides should be shoulders for fixing the U-shaped countertops. To firmly connect the rack and tabletop, you need to cut out plywood and attach 2 scarves from the bottom. Naturally, an angle of 90 degrees is observed everywhere.

Double-sided tape is glued to the grinding disc. Sandpaper is glued on top and cut along the contour. The disk is put in place, the table is assembled and the machine starts. A circle with an abrasive will wipe the countertop, widening the gap if it was cut too narrow.

Next, you need to close the disk from below so that the sawdust does not fly apart during operation. For this, a rectangular insert is cut out. It is fixed between the scarves and the countertop.

To protect the eyes from sawdust, a casing is made. To do this, a strip of plastic or tin is cut out, which is simply screwed over the disk to the table support.

To make a “dust extraction” for a vacuum cleaner, a sewer pipe discharged along the bottom is fixed under the disk below the machine. When it is cut, you need to leave the whole bell. Dust will fall into the trough obtained from it, and immediately be drawn in with a vacuum cleaner. If a gap is obtained when installing the pipe, then it can be closed with a thin rack.

This is an easy-to-manufacture grinding machine that does not dust during operation and allows you to save on consumables. For him, you can buy cheap paper and just glue it with double-sided tape. If you use a powerful motor for its manufacture, the machine does not slow down when grinding, like much factory equipment.

Share

Pin

Tweet

Send

Share

Send