Share

Pin

Tweet

Send

Share

Send

Sometimes the old tool loses its native handles, without which its use is significantly complicated. If desired, they can be restored in various ways, including by molding from plastic. It is especially good to do this from HDPE (high density polyethylene), which is used to make milk bottles. This material can be recognized by the marking "HDPE" or the number 2 inscribed in the triangle.

Materials and tools:

- tin can of suitable volume;

- thick metal lid for the can;

- white plastic bottles for milk;

- a bolt and 4 nuts corresponding to the size of the tool rod with a lost handle;

- an oven with the ability to accurately adjust the temperature;

- stir stick;

- gloves

- scissors for metal.

Handle manufacturing

To make the handle, you need to stock up on milk bottles. They are cut into small pieces. High density polyethylene gives strong shrinkage, so it is better to play it safe and prepare raw materials with a margin.

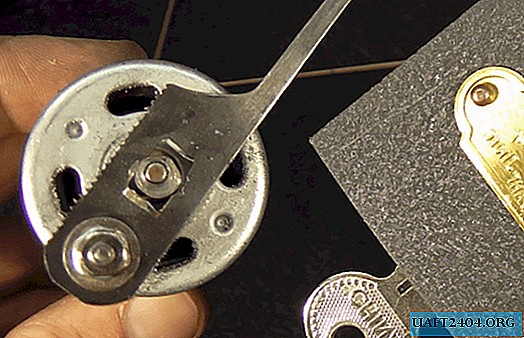

In order to smoothly press the nuts for screwing onto the tool rod into the formed workpiece for the handle, you need to choose a guide in the form of a cover on the form.

In such a cap, a hole is made in the center. A bolt with a nut screwed to the end is inserted into it, after which 3 more nuts are screwed onto it, as in the photo. They are pressed with keys so that they fit snugly on the lid.

Sliced polyethylene is laid in the jar.

After that, it is installed in an oven preheated to 180 degrees.

As soon as the mass acquires plasticity and is sealed at the bottom, still chopped bottles should be added.

As the polyethylene settles, you need to add recyclable materials until the can is filled with a completely dense mass.

Additionally, periodically tamp the molten plastic with a metal or wooden bar.

After filling the can, a lid with nuts preheated in the oven is pressed into it.

Hot plastic polyethylene allows you to do this manually. After waiting for the mold to cool completely, the upper lock nut and bolt are unscrewed, and the lid is removed.

To remove the sealed handle, the jar should be cut with scissors for metal.

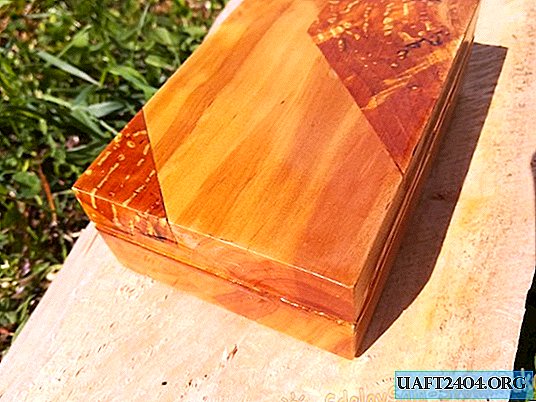

The result is a white polyethylene blank with an interesting black pattern resembling Damascus. Dark veins are obtained, since the milk can consists of 3 thin layers, the middle of which is black.

The workpiece is processed in any convenient way.

It can be grinded on an emery or lathe, holding the pre-screwed temporary bolt. The machined part looks very dignified. Since during its melting, HDPE cut into small pieces was used, the structure of the handle has no voids and other defects.

Application of this technology allows melting even in a kitchen oven. HDPE, unlike other types of plastic, gives much less smell when heated, at 180 degrees it does not boil and does not spread. The resulting blanks are easy to process, as they have a density of only slightly more solid wood.

Share

Pin

Tweet

Send

Share

Send