Share

Pin

Tweet

Send

Share

Send

Old hacksaw, old, unsuitable for regrinding, being a kind of hand saws for sawing wood, is a valuable material for use for any other useful purpose or application.

In fact, after all, tool steel of grades 8XF, 9XC, U7A, U8, U9A, U10 or steel grades 65G, 60C2A and others with high technical and operational characteristics go to the manufacture of such hacksaw blades.

We will try out of the available, unsuitable already for direct use, two hacksaws to come up with and implement some new device, useful both for traditional work and for non-standard use. Obviously, such a homemade product will not be superfluous in the arsenal of both a professional master and an aspiring amateur.

Making a metal cutter (guillotine shears)

One of the hacksaws is a cloth with a metal handle, and the other with a plastic one. Moreover, the second product from the edge opposite the handle on the canvas has a hole for which it can be hung on a nail driven into a wall or shield.

Taking the canvas with the hole as the template, with the help of a core and a hammer on another canvas mark the place for drilling the exact same hole.

Given the hardness and strength of the web material, drilling is carried out in two steps. First, with the help of an electric drill, we drill a small hole, greasing the place of contact of the tool and metal with oil.

Next, we drill it to the required size using a drill with a larger diameter.

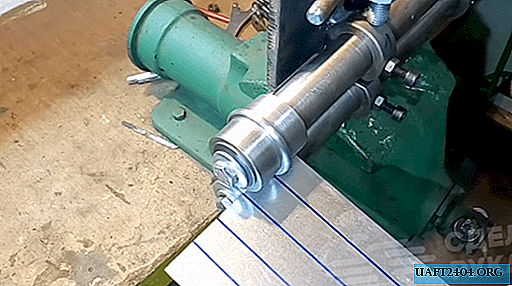

We connect the hacksaw blades, using the holes in them, using a suitable bolt, washer and wing nut. In this case, the teeth of the canvases are sent in opposite directions. That is, the back (smooth) sides of the canvases will become working parts.

We securely hold the blade of one of the hacksaws in a bench vise and we can assume that the home-made device for cutting various sheet materials is ready for use for a new purpose.

And so that the cutting process proceeds without the high expenditures of physical effort, and the work is of high quality, we lubricate the blades from the contact side along the entire length with any machine oil.

For cutting, we take the free blade up, turning it about the axis, the role of which is played by a bolt passed through the holes in the blades, and pressing them to each other. The second canvas all the time remains motionless, as it is clamped in a lock vice.

With this simple home-made tool, you can now easily cut any sheet of plastic, linoleum and even non-thick tin, including galvanized. The cutting line, regardless of the type of material, given the hardness and strength of the metal sheets, will always be flat, smooth, without burrs and bites.

If the cutting edges of a homemade torch become dull, then they can be easily restored on the emery wheel of a grinding machine or manually with an emery stone.

Share

Pin

Tweet

Send

Share

Send