Share

Pin

Tweet

Send

Share

Send

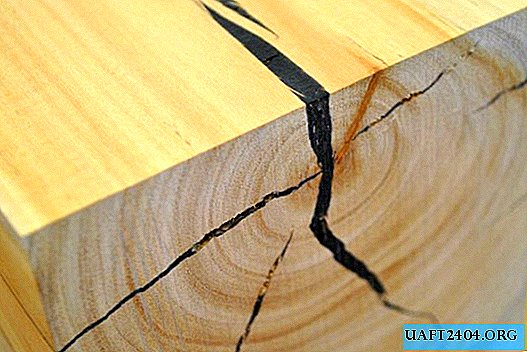

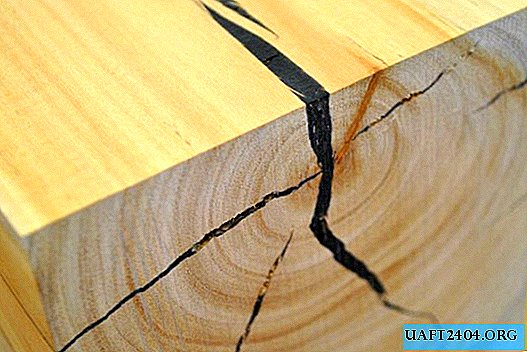

Small cracks in a tree are not dangerous and natural. It is bad when the defect reaches a width of 3-5 mm and spreads in length over the entire surface. Moisture that has fallen into the crack leads to decay of the tree. Bark beetles that settled there will undermine it from the inside.

Cracks form when the tree dries unevenly. Outside, the process is faster, inside - slower. Therefore, the inner layers are compressed, and the outer ones are stretched, the fibers break and cracks occur.

Now we will consider a way how to close a crack and use wood material for its intended purpose. What do we need for this?

Required materials and accessories:

- polyester resin in a set;

- small plastic container;

- construction tape;

- plastic wrap and plastic bags;

- stick or spatula for mixing;

- protective gloves and glasses.

Polyester resin is traditionally used for such a refurbishment. It easily penetrates into the fibers and forms a strong physico-chemical bond with them. Upon hardening, the resin becomes very strong, but at the same time retains some residual flexibility, which is very important, since the tree can narrow or expand depending on air humidity.

The process of closing a crack in a tree

Even a schoolboy can do this job. Only regular accuracy is required.

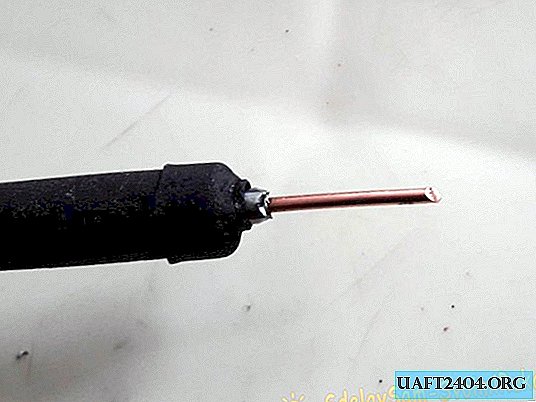

1. We seal the cracks at the ends of the wooden part and from below with tape so that the binder does not leak out through them. If the end surface is large, you can put a plastic bag on it and fix it with tape.

2. We prepare the working composition by adding a metered amount of catalyst to the resin, intensively mixing the ingredients for 1-2 minutes. The resin can be given the color of the material being restored by adding the appropriate pigment to it.

3. Pour the resulting composition into cracks until it completely fills their volume and spreads over the surface.

4. We wrap the treated wooden part in a plastic film, fix it in several places along the transverse perimeter with tape and leave it alone for 1-3 hours. This time is necessary for the complete completion of the polymerization reaction, that is, the final solidification of the polyester resin under the influence of the catalyst.

5. Expand the restored wooden part, remove the tape from the ends and the bottom of the tape. We mechanically remove excess hardened polyester resin from the surface. The restored wooden element is ready for work, both for decorative and for structural purposes.

In custody

A wooden part containing polymerized polyester resin can be treated without any restrictions with any tools: a saw, a plane, a grinder, a drill, etc. But only when processing with a chisel or chisel, you need to be careful and wear safety glasses, since the resin particles will fly apart like fragments glass.

And the last warning. The polymerization reaction of the polyester resin and the catalyst proceeds with the release of heat and styrene, which is harmful to humans. Therefore, all restoration operations on wood are best performed in the open air or in a workshop with reliable ventilation.

Original article in English

Share

Pin

Tweet

Send

Share

Send