Share

Pin

Tweet

Send

Share

Send

It is possible that a specialist in metal processing will have to drill high-speed steel grade P18. This will require a drill, the characteristics of which must exceed the material being processed.

The P18 quick cutter is tool steel that is used for the manufacture of cutters, drills, milling cutters, reamers, broaches, etc. With their help, structural steels having a strength of up to 1 thousand MPa can be processed.

Used materials and tools

For our practical experiment we will need:

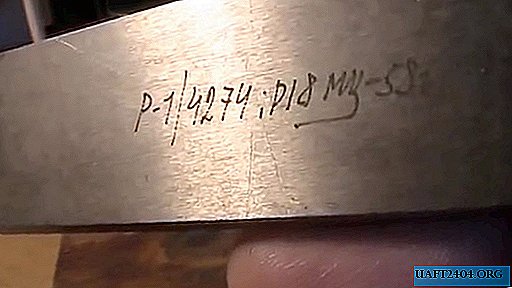

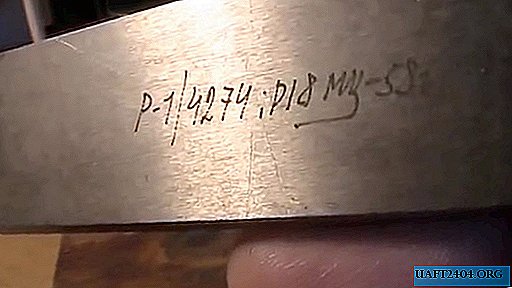

- Cutting tool made of P18 steel, manufactured back in 1958.

- Not a new feather drill with a diameter of 5 mm for ceramics and glass.

- Bench drill with adjustable spindle speed.

- Emery grinding machine.

- Calipers.

- Rough file for metal.

- A piece of square bar made of P18 steel.

- Cutter made of steel P6M5.

Test process

For the experiment, we settled on a cutting tool made of P18 steel, which was made during the Soviet Union, which is a reliable guarantee of its high quality. This is a fairly durable material. Apart from turning tools, various tools are made from it, which are used to process structural steels and other metals.

A 5 mm diameter drill bit, used and manufactured in China, which is usually used for metal, ceramics, glass and stone, was chosen as the test instrument.

To restore the cutting characteristics of this drill, slightly tweak it on the grinding wheel with a mechanical drive.

We insert the drill into the chuck of the bench drill and securely clamp with a key.

For reference, measure the thickness of the cutting part of the cutting tool with the help of a caliper. It turned out to be equal to 3.5 mm.

We are convinced that the vertical stroke of the spindle is sufficient for through-hole drilling of the cutter. To do this, you need to make sure that the end of the drill reaches the base plane and there is still some power reserve.

We start drilling, from time to time weakening the pressure on the tool. This is necessary for at least partial cooling and cleaning of chips and metal particles formed during drilling.

At the moment when the top of the tool comes out from the opposite side, we stop the process and turn the cutter to the other side. We put the drill at the mark and bring the process to the end.

The through hole in the area of the cutting part of the cutter made of P18 steel is ready! We spent no more than 2-3 minutes on this, without putting much effort, without complications, moreover, from one sharpening of the drill.

A coarse hand file for metal, of course, is not suitable for processing P18 steel, except that with its help you can remove the burrs formed during the drilling of the hole.

To check the results, we take a square bar of steel P18, drill it and make sure that the processing process and its results remain the same, no different from the first time.

Let’s try to drill a square with the same drill without regrinding, or rather, a cutter made of P6M5 high-speed steel, which has better cutting properties than P18 steel tools, especially at the permissible operating temperature. And with this material, the drill copes well.

Surprisingly, the usual cheap Chinese feather 5mm drill, which is designed primarily for working with ceramics and glass, easily drills not only high-speed tool steel P18, but also more durable - grade P6M5.

Final conclusions

We believe that with slightly more time and effort, the same result can be achieved using a drill made of the same P18 steel. Moreover, choosing the optimal speed, which clearly should be lower.

Periodic lubrication of the drill will also facilitate the process, which will contribute to better metal processing and somewhat cool the tool during drilling. You may need a few sharpenings.

Of course, one hole is easy to make. Here, special scrupulousness is not required, most importantly, perseverance and patience would be enough. But when it is necessary to drill at least a dozen holes in this quick cutter, then all the flaws of sharpening, drilling mode, lack of lubrication and tool cooling will play a decisive role.

Share

Pin

Tweet

Send

Share

Send